Mi heating cable

Description

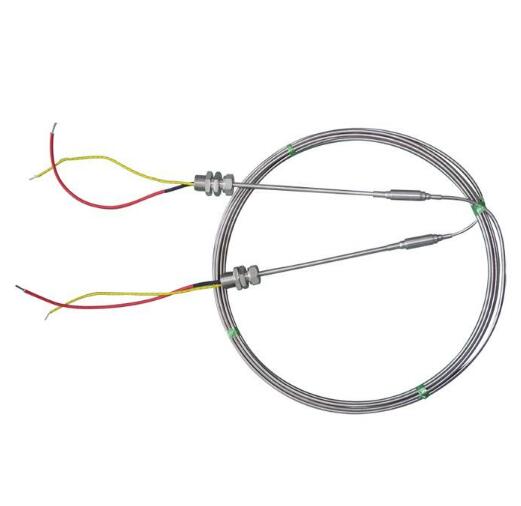

Introduction to MI heating cable

Mi heating cable is made by special production process with single or multiple alloy heating wires as heat source, high-purity high-temperature molten crystalline magnesium oxide as thermal insulator and seamless continuous stainless steel (304 / 316 L / 825 alloy) or copper tube as sheath. Polyethylene or lower can be added to places with strong corrosion effect.

Mi heating cable is also called Mi sheathed mineral insulated heating cable. The inorganic mineral insulator of the electric heating alloy wire (heater) and the outer sheath metal sheath extend for many times to form a solid body with high density. It can meet the requirements of high temperature conditions and large heating power (100 W / M), and the high withstand temperature can reach 600 ℃; The resistance range of the conductor is 4 ω/ Km to 25000 ω/ Km, with excellent mechanical strength and corrosion resistance. It is mainly used in nuclear industry, construction industry, metal manufacturing industry, tank barrel, container heating, high-temperature industrial pipeline heat tracing, process medium anti condensation and viscosity reduction, various industrial electric heaters and other fields.

Mi heating cable classification

Mi armored mineral insulated heating cable can be divided into single conductor Mi heating cable and double conductor Mi heating cable according to its structure. Generally, annealed copper is used as conductor, dense magnesium oxide is used as insulating material, and annealed copper pipe is used as sheath. Under special circumstances, a layer of plastic can be extruded outside the copper sheath.

1 stainless steel sheathed mineral insulated Mi heating cable.

2. Copper sheathed mineral insulated heating cable.

3. Copper nickel alloy sheathed mineral insulated heating cable.

Raw materials of MI heating cable core and protective wire sleeve

According to different heating constructors and temperature regulations, different raw materials of wire core and protective sleeve can be used according to table 1 and table 2.

Material list of MI heating cable core - Table 1

Core material Symbol Resistivity at 20 ℃ Service temperature limit

copper T one point seven two μ Ωcm2/cm 250℃

Copper manganese alloy M forty-one μ Ωcm2/cm 350℃

Constantan K forty-eight μ Ωcm2/cm 500℃

Nickel chromium alloy N one hundred and twelve μ Ωcm2/cm 1000℃

Material list of metal sheath of MI heating cable - Table 2

Jacket material Service temperature limit

copper 250℃

Copper manganese alloy 350℃

stainless steel 600℃

Inconel 600 600℃

825 alloy 800℃